Introduction

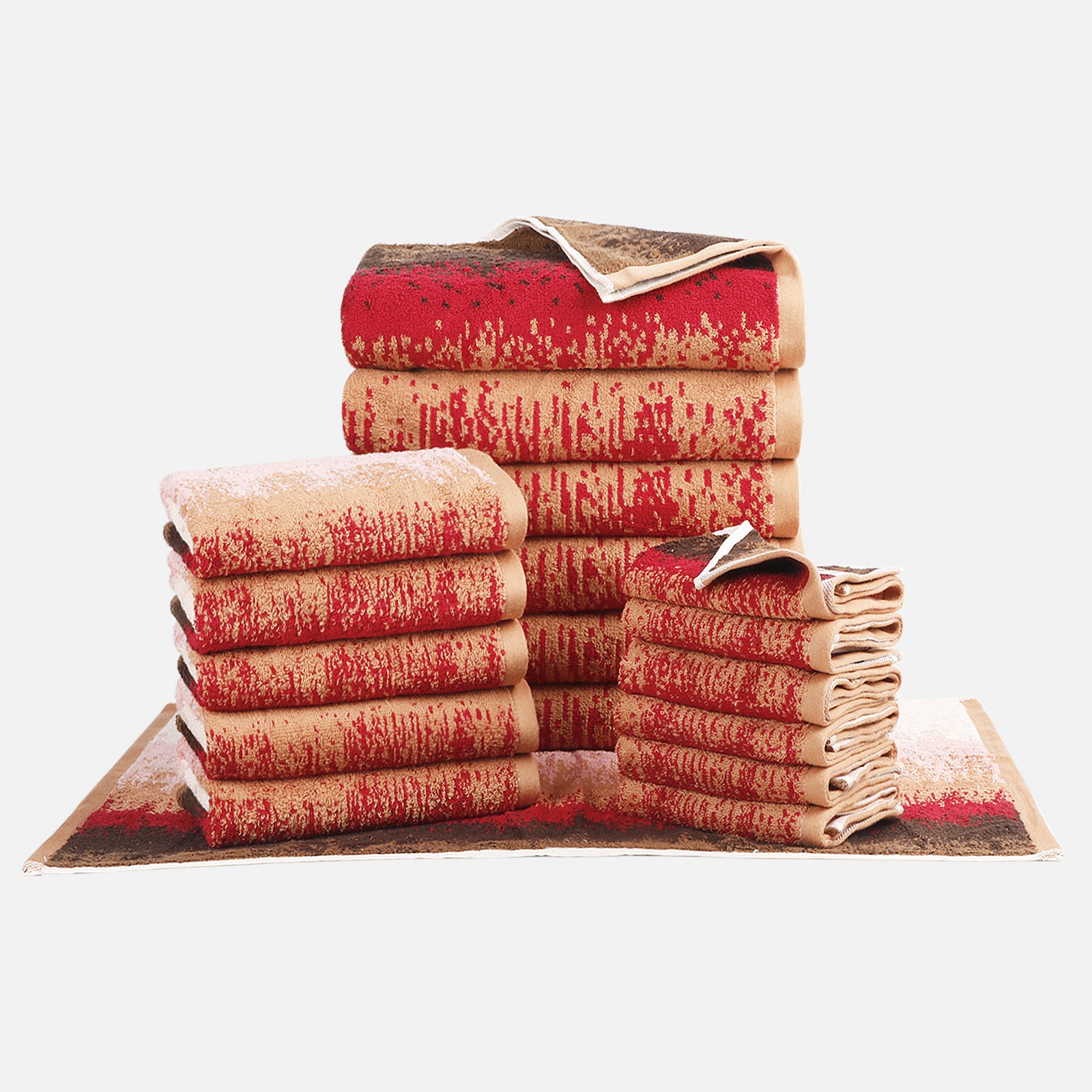

Towels are an integral part of our daily lives, serving a myriad of purposes from drying off after a refreshing shower to enhancing the decor of our bathrooms. But have you ever wondered how these seemingly simple, yet essential, household items are made? In this blog post, we'll dive into the fascinating world of towel production, exploring the intricate process from raw materials to the finished product.

The Raw Materials

The journey of a towel begins with the selection of raw materials. Cotton is the most common choice for towel manufacturing due to its absorbent qualities and soft texture. High-quality towels often use long-staple cotton, such as Egyptian or Pima cotton, as they are known for their durability and luxurious feel. Organic cotton is another popular choice for environmentally conscious consumers, as it is grown without the use of harmful chemicals.

The Production Process

-

Harvesting: Cotton is harvested from cotton plants when the bolls (the protective capsules containing cotton fibers) burst open, revealing the fluffy, white cotton fibers within.

-

Ginning: After harvesting, the cotton goes through a process called ginning, which involves separating the cotton fibers from the seeds and other impurities.

-

Spinning: Once the cotton is cleaned and processed, it is spun into yarn. This yarn can vary in thickness and texture, depending on the desired end product.

-

Weaving: The cotton yarn is woven into fabric on large machines called looms. The type of weave used can influence the towel's absorbency, softness, and durability. Terry cloth is a common choice for towels due to its looped surface, which enhances absorbency.

-

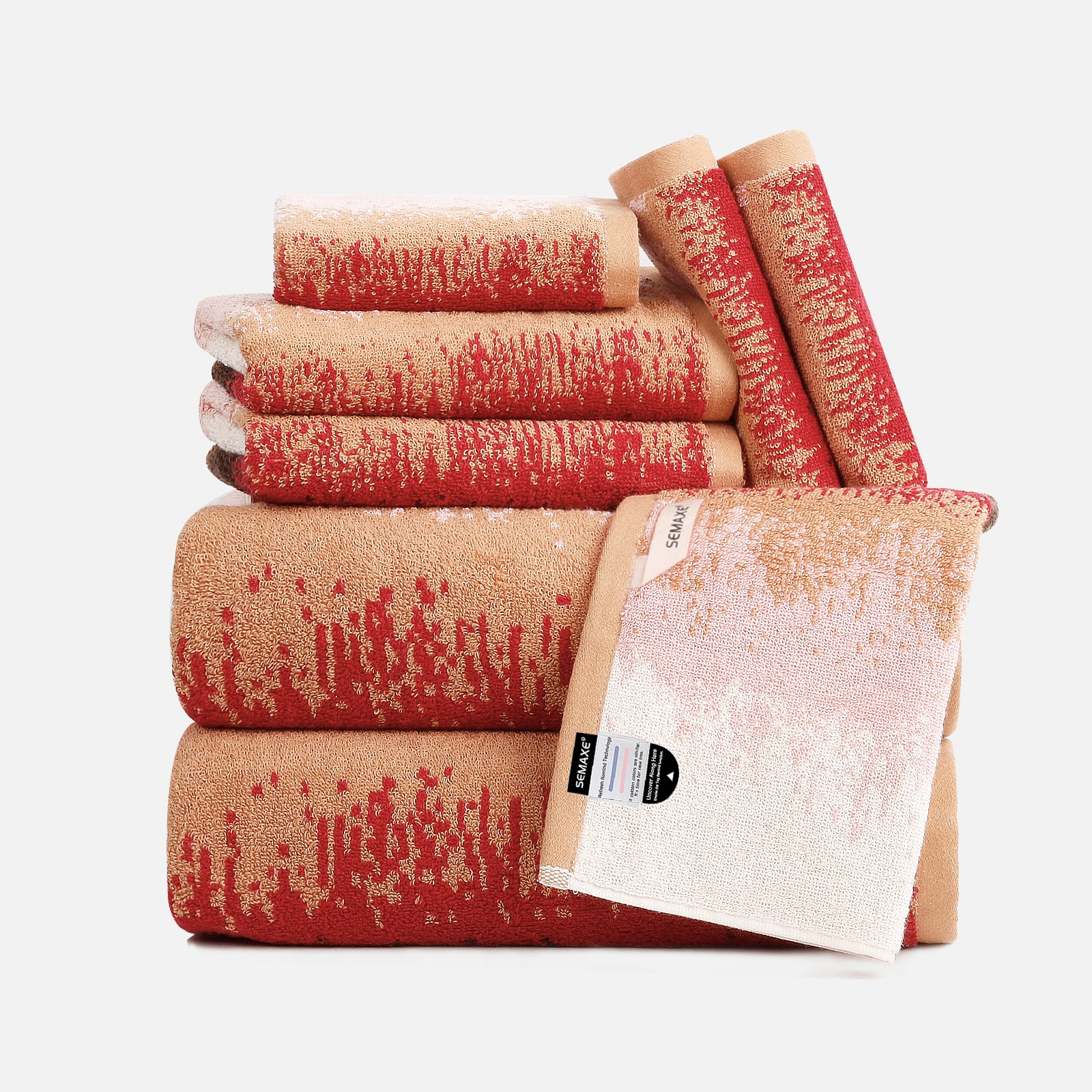

Bleaching and Dyeing: The woven fabric is then bleached to achieve the desired level of whiteness. If colored towels are desired, they are dyed during this stage. Towel manufacturers carefully control the dyeing process to ensure uniform color and prevent fading over time.

-

Cutting and Hemming: The fabric is cut into towel-sized pieces, and the edges are hemmed to prevent fraying. Towels can come in various sizes, from small hand towels to larger bath towels, and even beach towels.

-

Finishing: Towels may go through a finishing process, which can include brushing to make them softer and fluffier. They may also be treated to make them more absorbent and quick-drying.

Quality Control

Throughout the production process, quality control is of utmost importance. Manufacturers often conduct rigorous inspections to ensure that each towel meets the desired standards for color, size, texture, and absorbency. Towels that don't meet these standards are rejected, ensuring that only the best products reach consumers.

Environmental Considerations

In recent years, there has been a growing focus on sustainable and eco-friendly practices in the textile industry. Towel manufacturers are increasingly adopting practices such as water recycling, organic cotton sourcing, and reduced chemical usage to minimize their environmental impact.

Conclusion

The production of towels, a household item we often take for granted, involves a fascinating journey from the cotton fields to the finishing touches. Each step in the process, from selecting the raw materials to quality control, plays a vital role in creating the soft, absorbent, and durable towels that we rely on every day. Understanding the craftsmanship behind this everyday item can help us appreciate the effort and expertise that goes into making our towels not just functional but also a part of our home decor and personal comfort.